Aeroderivative Gas Turbine Maintenance

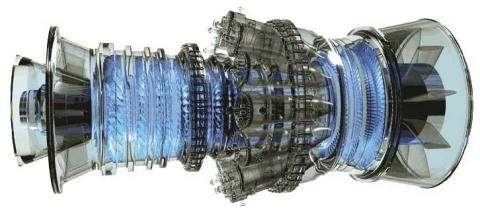

They include combustion liners cross-fire tubes transition pieces turbine nozzles turbine stationary shrouds and turbine buckets. Heavy-duty turbines 5 16 Small and micro gas turbines 6 17 Aircraft gas turbines 7 18 Gas turbine components 8 2 Fundamental Gas Turbine Cycle Thermodynamics 19 21 Reversible cycles with ideal gases 19 22 Constant pressure or Brayton cycle 19 23 Ideal inter-cooled and reheat cycles 25 24 Actual gas turbine cycles 34 25 List of terms and.

Repair Overhaul Component Repair Overhaul APM - A Division of AP4 Group has IGT Component Repair Overhaul capabilities at our headquarters in Lakeland FL USA.

. GEs total research and development budget for. The booster low-pressure compressor is derived from the. Aeroderivative Gas Turbine Operators and Manufacturers Maximize uptime and reliably predict remaining useful life for your aeroderivative turbine Gastops comprehensive solutions for operators and manufacturers of aeroderivative turbines give the industrys earliest notice of damage progression abnormal wear trending and prognostic information.

Test capability required Level V Level IV plus repair of piece parts and control and accessory items. The aeroderivative gas turbine is a type of gas turbine with a lighter weight. Alert 16 ins.

With our highly competent team of experts on aeroderivative turbines and auxiliary equipment we can provide manpower support to our customers at all levels in mechanical electrical and control engineering. These small units are often isolated without easy acces to competences strongly dependent from OEM. The LM6000PF aeroderivative gas turbine is designed to extend those intervals to 10000 30000 and 60000 hours.

LM6000 aeroderivative gas turbine. Aeroderivative gas turbines with power output ranging from 13 to 47 MW. This project taps the large deep water pre-salt oil and gas reserves of Brazil.

Learn more Grupo Losán boosts reliability and efficiency with GEs Engine Exchange Program Maintenance and repairs solution cuts aero outage time in half. The gas turbines are comprised of a compression mechanism to help the. Level IV Level III plus complete disassembly and assembly of EMUs.

In fact they are designed to mix fuel and air and then ignite to produce the desired yield. Level III Level II plus disassembly and assembly of gas turbine down to EMU Engine Maintenance Unit level. Typical aeroderivative gas turbines have maintenance intervals of 8000 25000 and 50000 hours.

This significantly increases the units availability and productionwhich is particularly ideal for LNG plants. Allows replacement of any individual piece part. The core high-pressure compressor combustion chamber and high-pressure turbine is from the widely referenced LM6000 aeroderivative gas turbine with over 1300 installed units and 40 million operating hours in the field.

32 SGT-A35 Industrial RB211-GT62 generating sets. Free turbine Inlet. Our focus is twofold.

On the support maintenance and overhaul of aeroderivative gas turbine prime movers in electrical generation and natural gas compression service. We have aeroderivative gas turbines driving mainline pumplines. Minimum downtime for inspection and overhauls On-site inspection and maintenance.

You can lease gas turbines from GE when your own turbine is at a depot for repair or when it cannot be repaired on-site within a reasonable amount of time. Repair Overhaul - AP4 Group - Full-Service Heavy-Duty Aeroderivative Industrial Gas Turbine Maintenance Provider. Company Aeroderivative Aeroderivative Your Reliable Source for Gas Turbine Parts Services APM stocks an expansive inventory of aeroderivative parts for GE LM series engines through our reliable partnerships around the world.

Advantages of gas turbines The capability of supplying relatively large amounts of power given their size A long life and low maintenance. Although it is classified as a gas turbine the source of fuel for an aeroderivative turbine is not gas. It discusses opera-tional and economic considerations resulting from GEs aeroderivative gas turbine design philosophies and the value of these considera-tions in a customers gas turbine selection process.

Keeping units competitive and reliable now entails the dicult task of balancing appropriate costs. The engine combines aeroderivative and frame technologies. Maintenance Repair Solutions Aeroderivative Gas Turbines In the current future heat and power generation market Aeroderivative Gas Turbines play a key role.

Support maintenance and overhaul of military aircraft engines and naval main propulsion aeroderivative gas generators. There are casing vibration sensors installed to monitor vibration as follows. Our wide range of manpower pool allows us to build teams with various competencies ranging from helper level to sitemaintenance supervision complete project.

The largest single order for the SGT-A35 Industrial RB211 to date adds to a large fleet already operating. Trip 3 ins 2. These days the aeroderivative models are becoming more popular for use in electrical power applications though more for peak and intermittent purposes rather than base power generation.

Alert 13 ins. Full Overhaul of Hydraulic Actuators. Aeroderivative - AP4 Group - Full-Service Heavy-Duty Aeroderivative Industrial Gas Turbine Maintenance Provider.

Why lease an aeroderivative gas turbine. The recommended maintenance of most manufacturers for heavy-duty gas turbines is oriented toward.

Why Aeroderivative Gas Turbines Make Sense For Cogen Power Engineering International

Gas Turbine Selection Heavy Frame Or Aeroderivative

How Can You Prevent Wear On Aeroderivative Gas Turbine Machinery With Atten2

Comments

Post a Comment